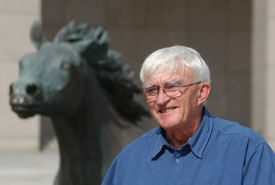

| Sculptor

Robert Glen was commissioned to sculpt these nine mustang horses

which were placed in Williams Square, Las Colinas, Irving, TX. The

research for the authentic "Andalusian Horse" was done

in Spain, where evidence was found of the Spanish Conquistadores

taking horses to Texas and Mexico in the 17th century. Some of these

horses went wild and become known as Mustangs. The initial models

for this sculpture were made in Robert Glen's studio in Africa.

They were then cast in England and flown to Dallas, TX. The final

installation in Williams Square was completed in 1984.

The Mustangs of Las Colinas, a modern-day equestrian sculpture,

was planned and executed as a memorial to the evolving culture in

North America. This monumental sculpture memorializes the heritage

of Texas, recognizing that Texas is not only a geographical place

on this continent, but that it represents a distinctive spirit and

way of life of a people who are committed to the freedoms of action,

initiative, and expression for each individual man and woman as

no other culture before has exhibited. Texas is the land of the

entrepreneur, a citizenship of individuals, a land of the free spirit.

How

"The Mustangs of Las Colinas" Were Created

Robert Glen was given the assignment to create the mustang sculpture

in the summer of 1976. The plan for a large plaza, the size of two

football fields side by side, paved in Texas pink granite, was described

to him by Ben H. Carpenter, the developer of the project. He was

asked to create a band of mustangs crossing a stream of water in

the middle of the plaza proportioned so that they could be viewed

from any direction. The plaza would be bordered by granite clad

buildings on three sides with a fourth building possibly to be added

across the boulevard.

Glen spent a year of research prior to starting the actual sculpting

process. He read books and historical periodicals to fully understand

the background of the magnificent animals that were brought to the

American continents from Spain and which sired the original wild

horses of Texas and the western United States. He discovered that

the wild horses presently in the preserves and parks reflected subsequent

crossbreeding unlike the Spanish ancestry of the original mustangs.

Glen was sent to southern Spain in search of authenticity. There

he studied horses with the same pure bloodlines as those of the

specially selected animals taken to Mexico and Texas centuries before.

Following the same research techniques applied to his African wildlife

sculpture, Glen used a number of anatomical castings, taken from

dissected animals, to study the anatomy and muscular and skeletal

systems prior to beginning his sculpting.

First Glen constructed a number of small scale model horses in various

positions and movements reflecting the mood and motion of the concept

that had been given him. During this stage he made 47 different

models before a final scale model, less than 1/8 lifesize, became

a three-dimensional outline for the next stage of the sculpturing

process, as well as serving as a model around which the plaza design

details could be further developed. The next phase of the process

required that larger working models be made from which more accurate

measuring could be done. This intermediate state, modeled in a pliable

plasticine material, was fashioned by Glen at 1/2 of lifesize, which

would be 1/3 of the final 1 1/2 times lifesize monument.

Modeling was done in plasticine, considered an improved material

over clay for this type of work, to facilitate greater detailing.

Since plasticine is a soft and easily damaged material Glen made

molds of each of the 1/3 final size animals he had created in his

studio and cast them in fiberglass. This intermediate stage, in

the form of a fiberglass maquette, would ultimately be shipped from

Glen's Nairobi studio to the foundry in England where the final

1 1/2 lifesize models would be completed and cast. Glen used a mixture

of fiberglass and resin in which to cast a lightweight yet durable

model that would endure the trip from Nairobi to England. The Nairobi

studio was the site of this repetitive process for each of the nine

mustang animals that would compose the completed sculpture; five

mares, two colts, a young stallion, and an older stallion dominating

the band of mustangs. The fiberglass maquettes were cleaned and

prepared for shipment to England. Glen made finishing touches to

each of the fiberglass maquettes. Prior to shipping from Nairobi

the preciseness of the detailing of hair, mane, nostrils, and the

muscular appearance of the surface of the maquette was carefully

checked.

Each

fiberglass intermediate size maquette was crated and shipped by

air from Nairobi to the Morris Singer Foundry at Basingstoke, England,

about an hour's drive from central London. This world famous foundry

has cast the works of such famous sculptors as Jacob Epstein, Hamo

Thornycroft, Barbara Hepworth, Dora Gordine, Oscar Nemo, Enzo Piatta,

David Wynne, Henry Moore, Reg Butler, Eduardo Paolozzi, and Kym

Chadwick. Periodically, Glen flew to England and spent several months

at a time in the foundry where the final process of creating the

1 1/2 lifesize model was begun, using the intermediate size maquette

as a scaling and measurement guide to be cast in bronze.

The enlargement of realistic forms such as the mustangs is a complex

process dealing with the volumetric problems brought on by varying

forms and densities. A three-dimensional pantograph was constructed

to produce the enlarged models. Using the pantograph, a "cut

out" in a light foam material was assembled and fitted to a

metal frame or armature. The shape formed by these assembled "cut

outs" were purposely slightly undersized so as to provide a

reasonably accurate enlarged form in the shape of the intermediate

maquette but providing a modeling surface upon which a final coating

of plasticine could be applied and sculpted.

The plasticine coating covers the armature form which was created

by the pantograph and enlarged to three times the size of the intermediate

size maquette shipped from Nairobi. The completed plasticine model

of the young stallion hangs suspended within a frame, awaiting the

next step, preparation for final mold making preceding the actual

bronze casting. Each horse, when completed, had one to one and one-half

tons of plasticine on its frame and the armature weighed about half

a ton. The bronze casting required that each of the final sculpted

animals be cut into several sections. Therefore, the surface of

the soft plasticine modeling material had to be made firm so that

it could be handled during the cutting and strong enough to go through

the mold-making process. Robert Glen devised a simple system of

painting thickened polyester resin over the completed plasticine

surface which hardened in about fifteen minutes. This also preserved

in its final form the impression of hair created by delicate brush

strokes applied to the plasticine surface in the final detailing

process. Later in this process the cast bronze tail will be united

with the other sections of the casting which compose the animal.

Each portion of the final model was packed in silica sand within

a sectional steel box.

The silica sand compound containing a small percentage of water

and sodium citrate is set to the consistency of sandstone by permeation

with CO2 gas. The reaction of the ingredients in the sand with the

gas hardens into a reverse or negative mold around the model within.

When the steel sections of the box are dismantled the hardening

sand mold around the plasticine model is removed. These reverse

sand molds are fitted together within another steel box, leaving

a hollow void where the model had been located in the first steel

box. This hollow void is then filled with sand, which in turn is

hardened by the gas permeation technique producing a positive solid

core mold of the maquette.

The internal solid core positive mold of sand is trimmed to an undersized

shape in order that when it is fitted back together with the corresponding

negative sand mold a gap of open space will exist between the two.

Steel pins are used to maintain proper spacing of the relationship

between the positive and negative molds of hardened sand. Then molten

bronze, heated to a temperature of 1150 degrees, is poured into

the open gap between the two sand molds. When cooled, the casting

is exposed by removing the metal casing and smashing away the sand

mold. Not until this point was it known that the cast was a good

one.

Following removal from the sand mold box, the bright bronze metal

castings were examined, cleaned, and touched up. Metal finishing

removed any excess bits of bronze from the edges and each bronze

piece was prepared and assembled for welding together with other

sections of the sculpture. Bronze welding was used to chase all

seams together for a unified surface. In one case, a tail was cast

in no less than 34 separate pieces and then welded together. During

this process, Glen was joined by foundry managing director David

Vallance and foundry superintendent Arthur Markwell in supervising

the final assembly of the castings. Bronze welding was done both

inside and outside each section. The Morris Singer Foundry, whose

heritage includes the casting of public monuments around the world

such as the famed Lions of London's Trafalgar Square, is one of

the oldest continuing sculpture foundries in the world. Founded

in 1848 by John Webb Singer, utilizing British, French and Belgian

artisans, it was merged in 1927 with the Morris Art Bronze Foundry

and in 1973 with the Paris sculpture foundry, Susse Fondeure S.A.

In addition to sand molding, another ancient and time consuming

process is the assemblage and finishing of the resulting bronze

castings. The few experts for large scale castings available today

have studied and worked in it most of their lives. Foremost among

them are the artisans at the Morris Singer Foundry.

The bright and shining bronze mustang castings were assembled in

the foundry yard one by one as they were completed. The five mares

and young stallion were to be joined later by the two colts and

the older stallion. These bronze figures, however, form only a portion

of the sculptural presentation. At this stage they are yet to be

united with the granite clad environment in which they will be permanently

situated within the moving stream designed to enforce and accentuate

the perspective of motion and movement.

The bronze casting process itself was completed on November 10,

1981. The London firm of Evan Cook was engaged to prepare the bronze

sculptures for shipment to Texas. A decision was made to make the

shipment by air rather than by ocean. At the Basingstoke foundry

each bronze sculpture, weighing approximately two tons, was loaded

and taken to Cook's packing warehouse. There, specially designed

crates for each individual horse were installed to protect them

en route. They were then transported to Heathrow Airport outside

London.

At Heathrow Airport the 17-ton cargo of nine bronze mustangs was

loaded onto a Pan American Airways 747 cargo plane and flown across

the Atlantic to Kennedy Airport in New York City. Las Colinas Corporation

sent a representative to accompany the sculpture while they were

in transit. In New York, the bronze horses were transferred to an

American Airlines 747 freighter which flew the cargo to Dallas/Fort

Worth International Airport, adjacent to Irving. Upon arrival at

D/FW Airport, the cargo of mustangs was unloaded from the plane

and brought overland to Las Colinas. Meanwhile, during the several

years in which the sculpture pieces were being created, enlarged,

cast and finished in bronze, the architectural firm of Owings, Skidmore,

and Merrill had been engaged to design the complex of buildings

which would surround the plaza. The complex of granite-clad, copper-roofed

buildings, designed by Charles Bassett, a principal in the San Francisco

office of the architectural firm, was well under construction and

partially occupied at the time of the arrival of the bronze mustangs.

In a nearby staging area the mustangs were assembled in a mock-up

of elevations and positioned as they would relate one to another

on the plaza. Meanwhile, James Reeves, the landscape architect and

planning engineer, had designed the layout plan for the stream in

the middle of the plaza that the horses would be crossing. An 8,000

pound concrete plinth was made as a base for each horse. An intricate

pumping system was designed to suggest the splashing of water around

the hooves of the horses, crossing in midstream. Following the installation

of the horses in the stream the piping for the water and fountain

system was completed and the bottom of the stream bed was covered

with a pebble-like finish.

The last stages of the installation were carefully supervised by

Glen. Specialists from the Morris Singer Foundry flew to Texas to

assist in cleaning the bronze surface of the installed horses by

blasting the sculptures with tiny particles of plastic under high

pressure. This process returns the bronze to the gold-brass coloration

it had as it emerged from the molds at the foundry. In earlier years

people tried to retain the bright new look of bronze. In more recent

times, however, the vogue has been to rapidly influence the oxidation

or patination of bronze sculpture by inducing with acid mixtures

a specifically designed coloration or effect. It was decided not

to chemically induce an accelerated oxidation on the mustang pieces,

but instead to permit them to age naturally, evolving their patina

over time, responding to the natural environment as God will have

it. Periodically the bronzes are coated with a thin wax material

to minimize an accelerated discoloration.

Finally, on September 25, 1984, eight years after the project was

conceived, the sculpture was in place and the plaza was open for

the public to inspect and enjoy. Assembled together at last were

the nine bronze mustangs, forming the largest equestrian sculpture

in the world. The plaza has become a place for public gatherings,

symphony concerts, and other intellectual and recreational pursuits.

The centerpiece of the plaza, "The Mustangs of Las Colinas",

shall be a lasting memorial to the vanguard of the civilization

of Texas.

Robert Glen thanks the Dallas County Utility and Reclamation District

for its courtesy in allowing this article to be reproduced. ©1988

Dallas County Utility and Reclamation District |